Note – this page is adapted from the original Design Day website of the Hajim School of Engineering, University of Rochester. The original site includes a video presentation and comments from faculty.

UPDATE – This design was recently patented! The published patent can be found here.

Team

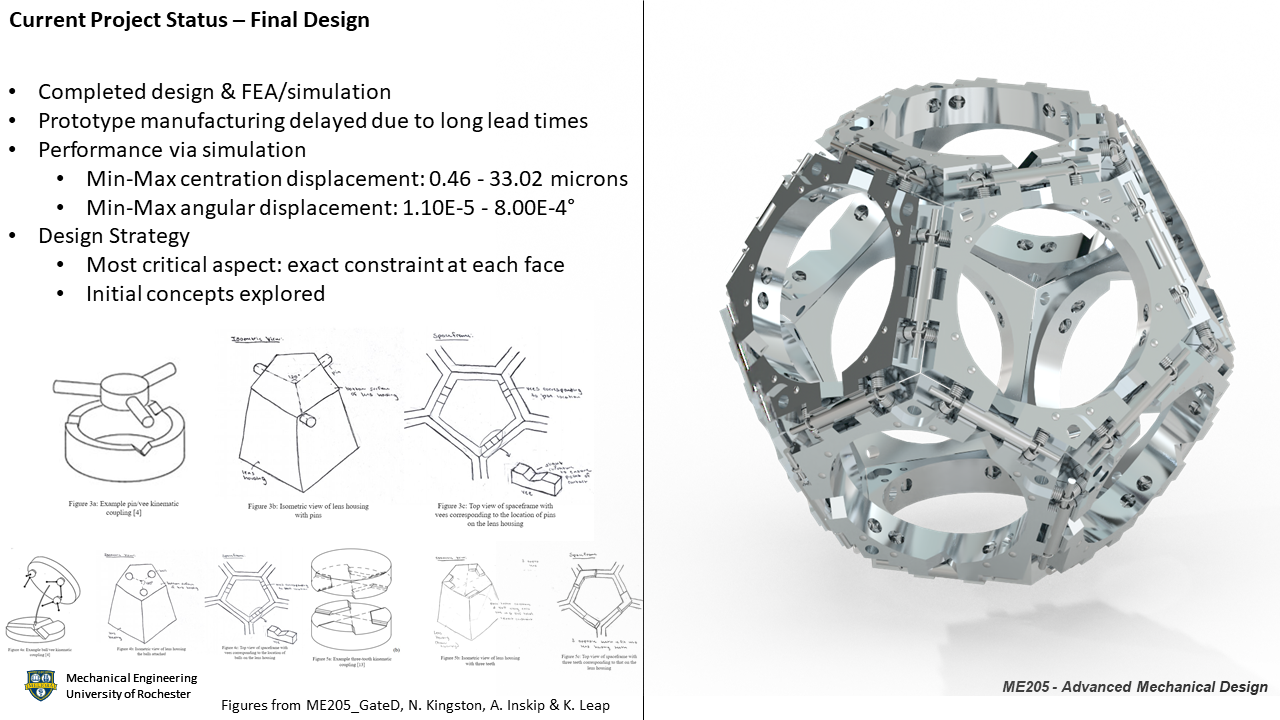

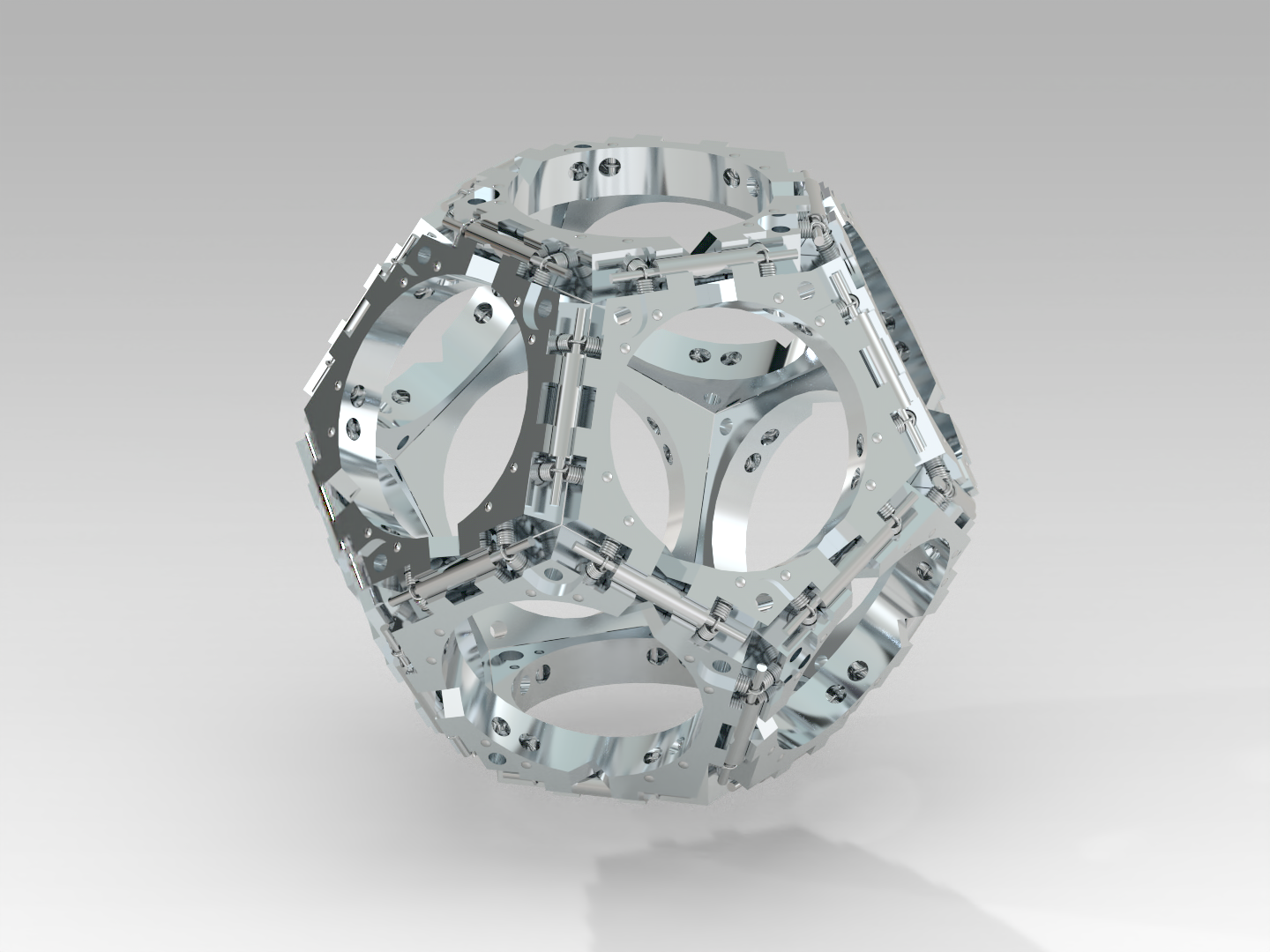

Final Rendered Spaceframe

Project Description

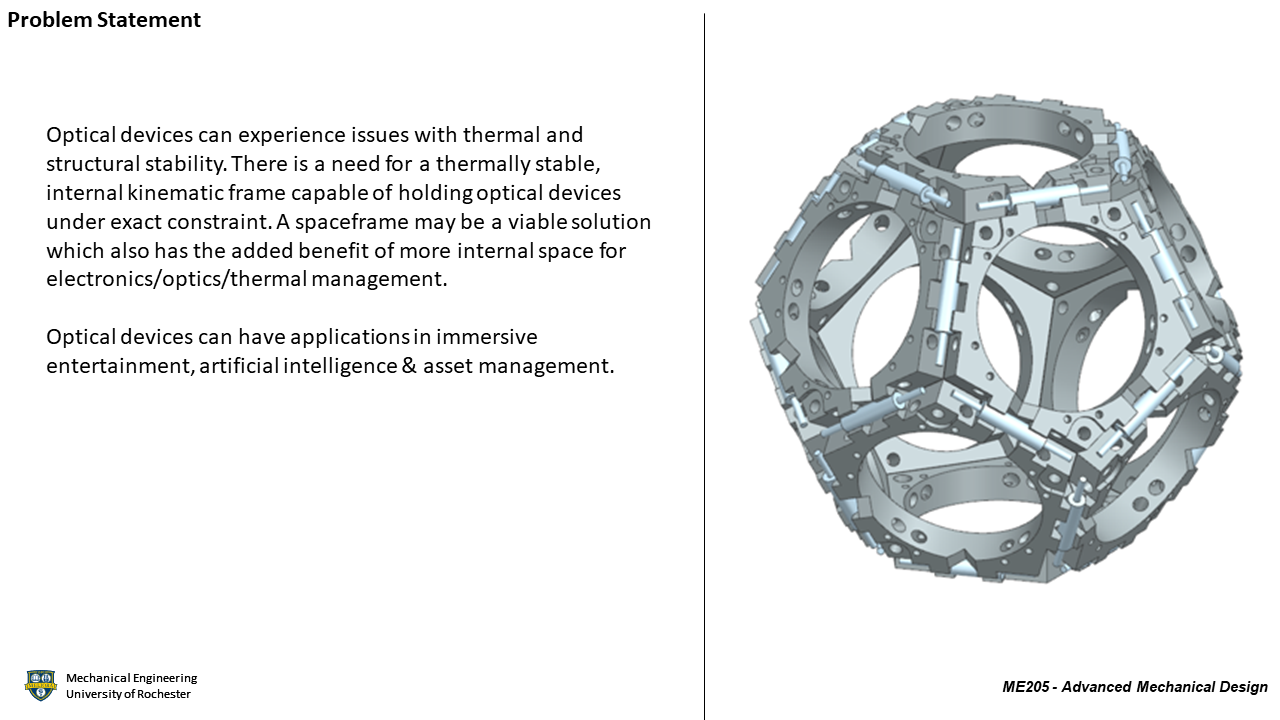

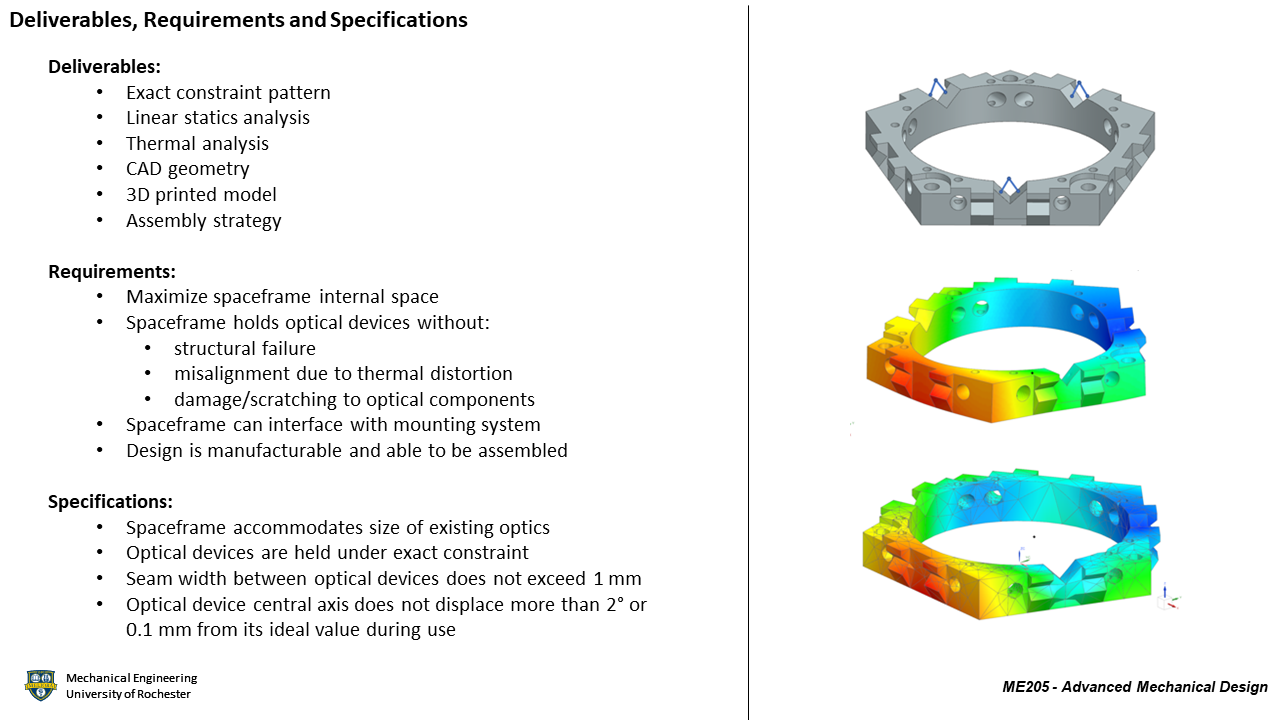

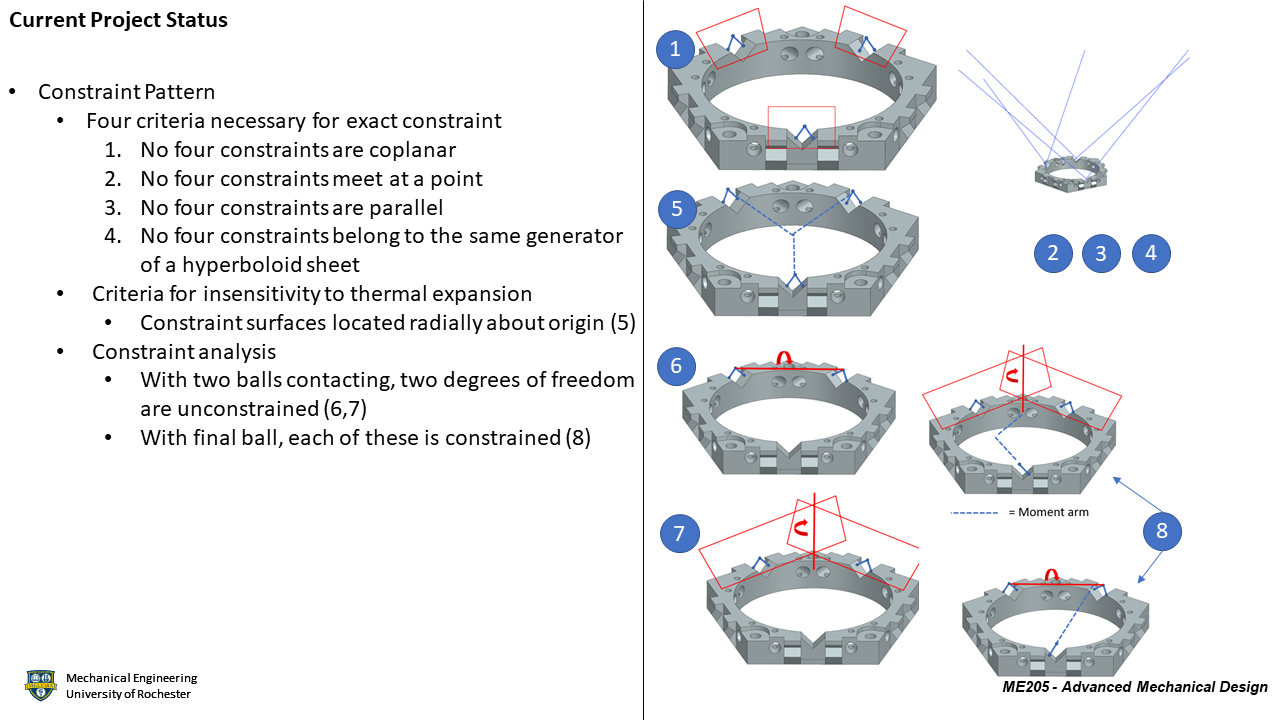

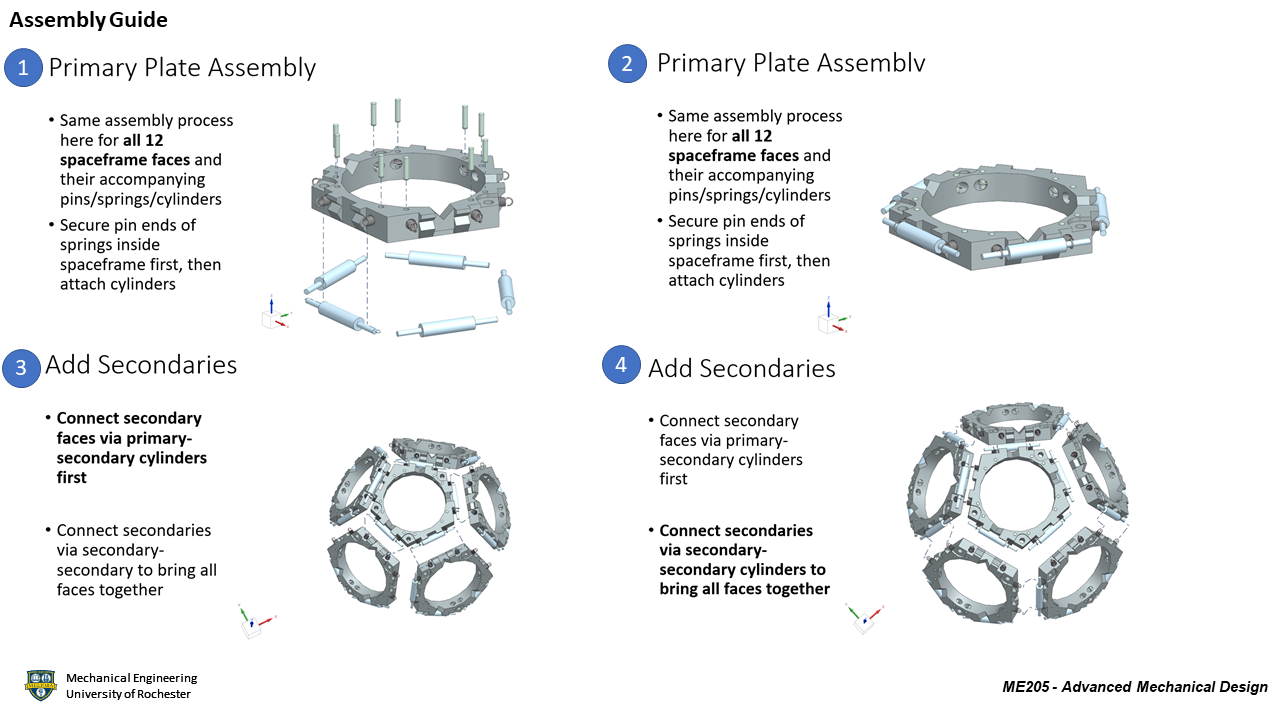

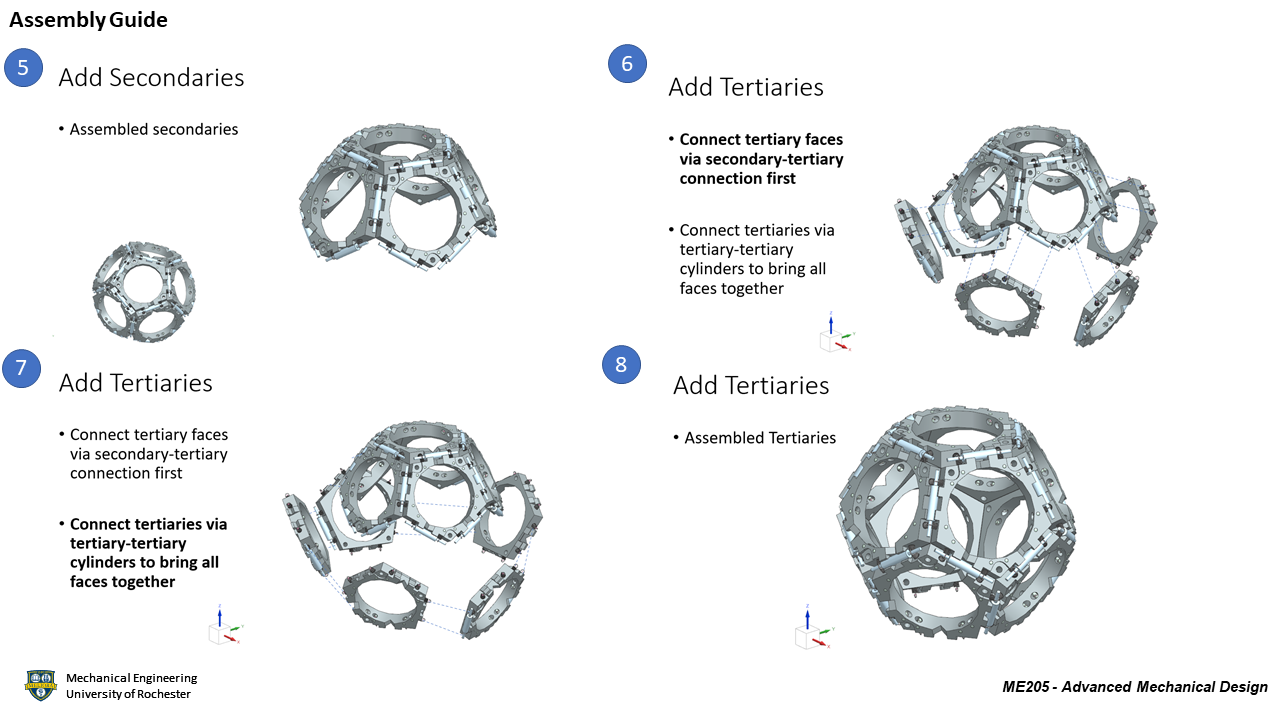

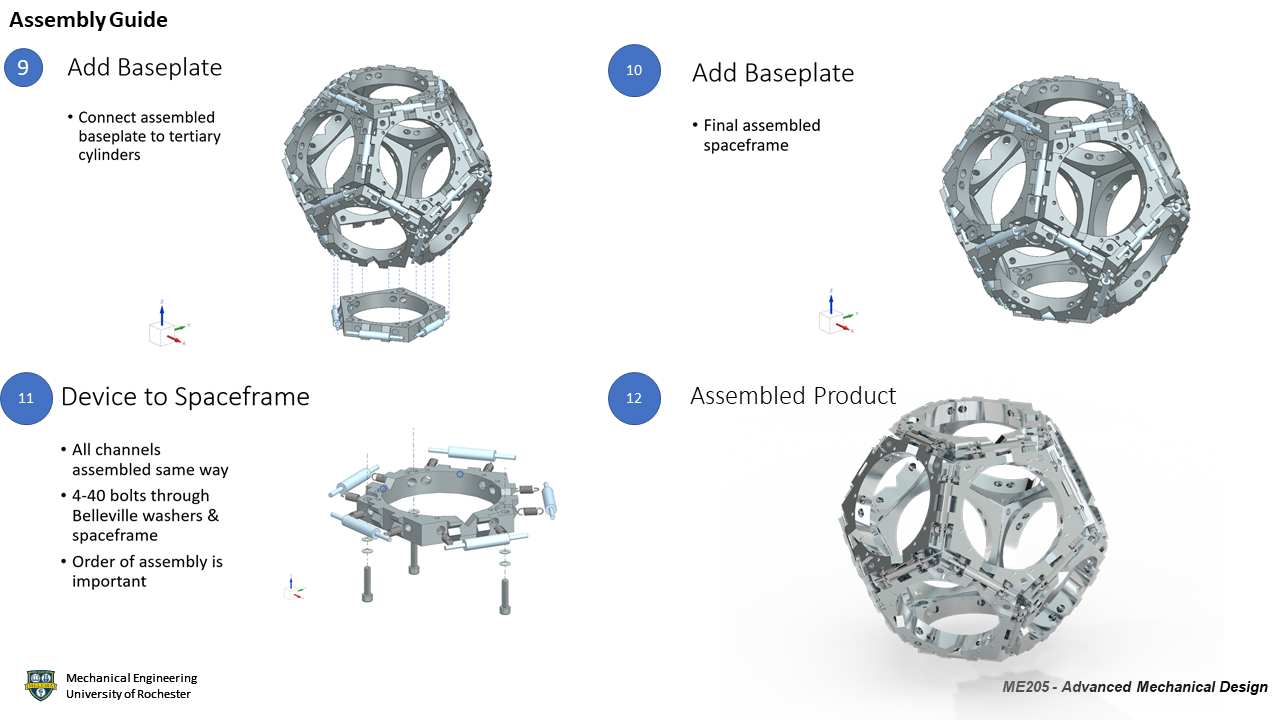

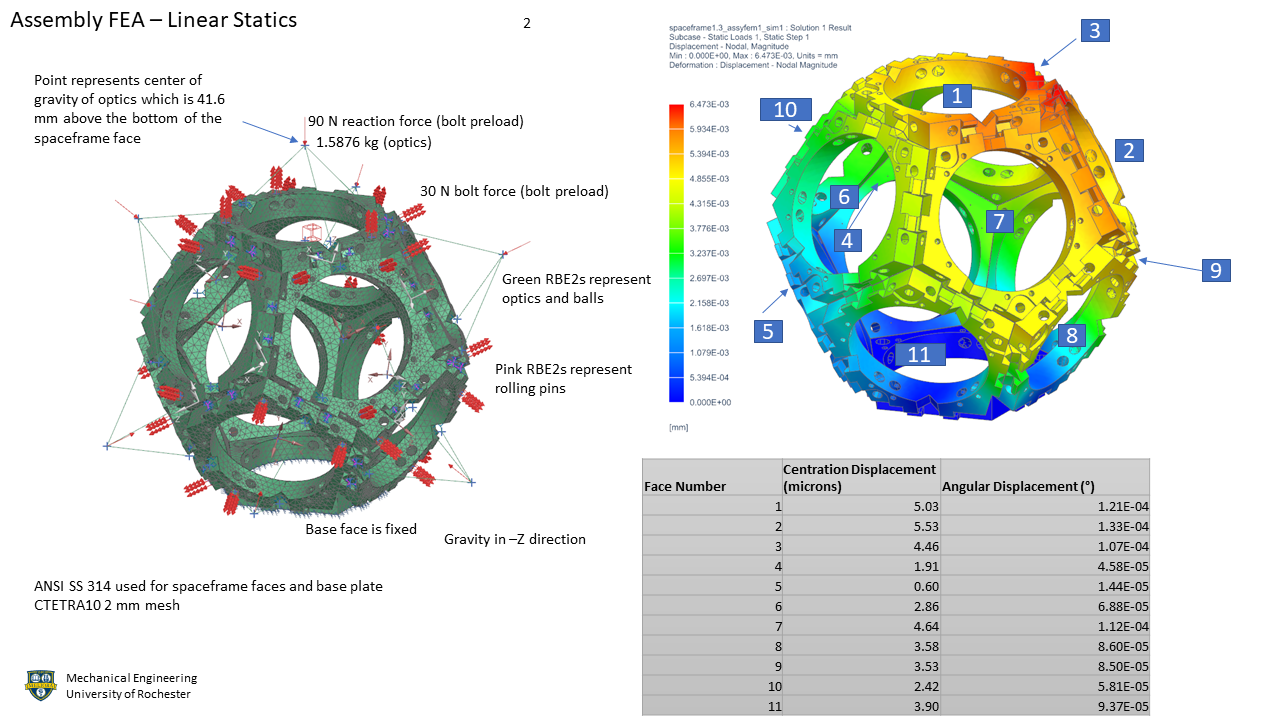

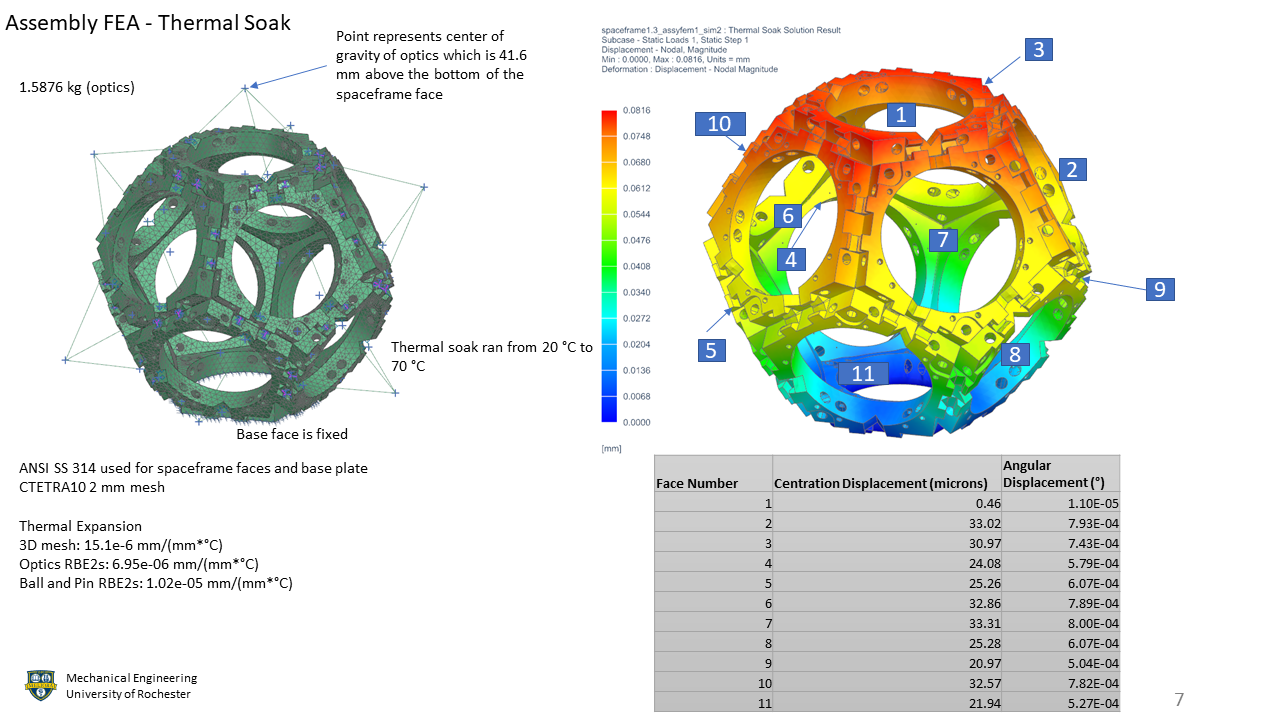

Several optomechanical applications have a need for a 360° kinematic mounting system capable of withstanding thermal loading due to heat generation from electronic devices. It is advantageous for optical systems to have a repeatable and controlled, known distance between devices such as optics, sensors, light sources, mirrors or assorted non-optical sensors. A geodesic dome utilizing exactly constrained kinematic couplings at each face enables the connection of any of these devices to the spaceframe in a thermally stable, exactly constrained configuration. This permits 360° mounting, capable of mounting a variety of components in any number of spherical, 360° configurations. Each one of these components is capable of mounting in a manner such that it is directed either inward toward a controlled point at the center of the spaceframe, or outward radially around the spaceframe. Some of these applications involve precise measurements, and positional displacements on the order of microns can affect accuracy. The team was able to design a spaceframe capable of staying under this displacement with high thermal loading applied.

Presentation

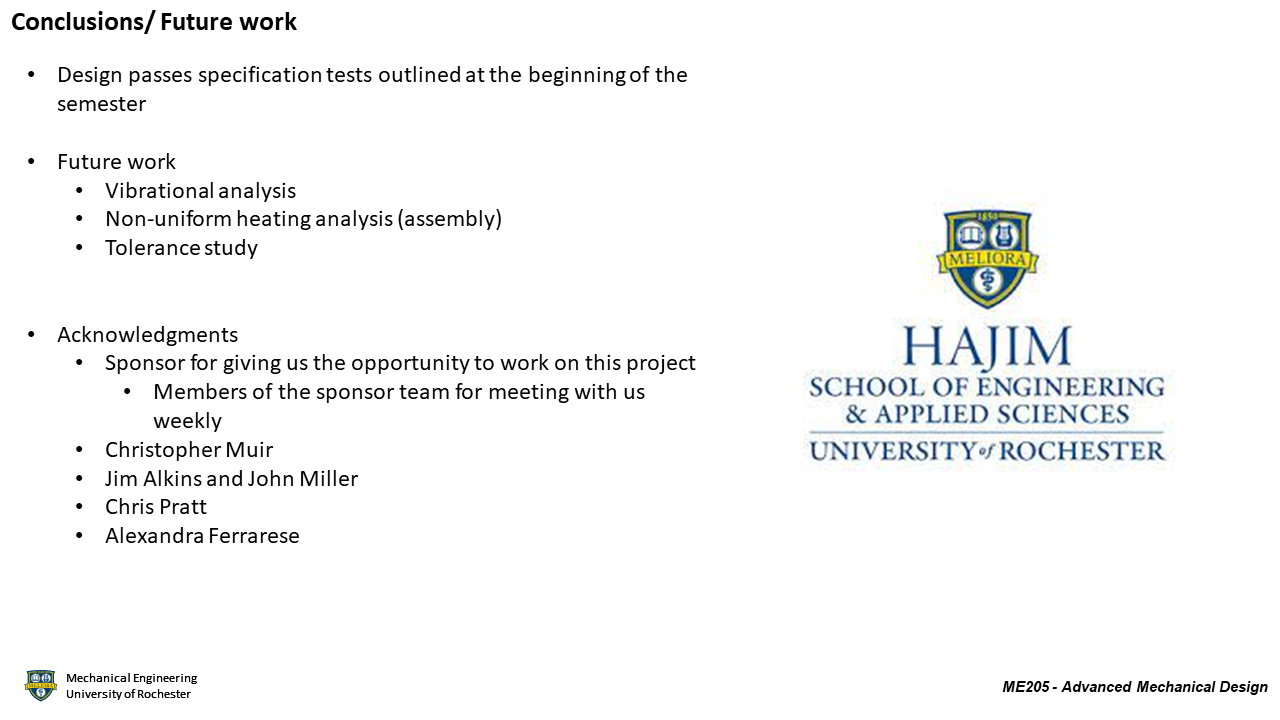

To conclude the Advanced Mechanical Design course, a final presentation was produced and presented, and the slides can be viewed below. The presentation before university staff and faculty is unavailable due to NDA restrictions. A modified version of the presentation is available on the Hajim School of Engineering Design Day website.

Interactive Model

Acknowledgments

The 360 Optical Mounts team would like to thank Professor Muir for his continued support of all of the teams efforts throughout the semester. We would also like to thank Jim Alkins, Chris Pratt, John Miller, Derick White and all the ME 205 TAs for their support in design, review and manufacture. In addition, thanks go to Alex Ferrarese for handling material and component purchasing and enabling the project to be completed.