For a Mechanical Design class project, the goal was to improve the strength-to-weight of a hook assembly under three load cases to produce highest metric compared against peers’ designs.

Design Constraints

- Additive/subtractive geometry changes only.

- Material: S/Steel_PH15-5 (NX Material Library) (145ksi yield)

- Fixed constraint SPC123456 on base

- Originally across the full flat base

- Modified to apply to four 0.5” radius stress risers under bolts

- 1900lbf preload applied over bolt surfaces

- Load cases:

- 1250 lbf horizontally in +X direction

- 1875 lbf at 45° below horizontal

- 2500 lbf vertically in -Z direction

Base Case

- Base Case:

- Worst-case metric used for load case testing

- Initial strength-to-weight (SW) = 816.3794

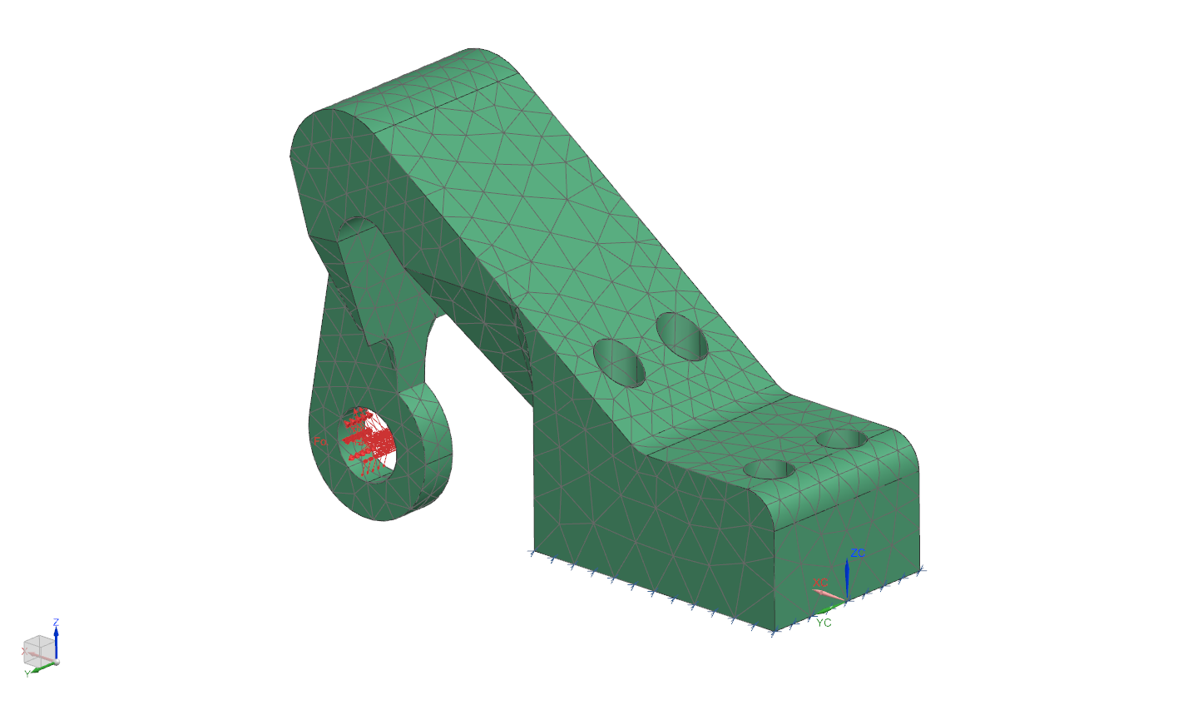

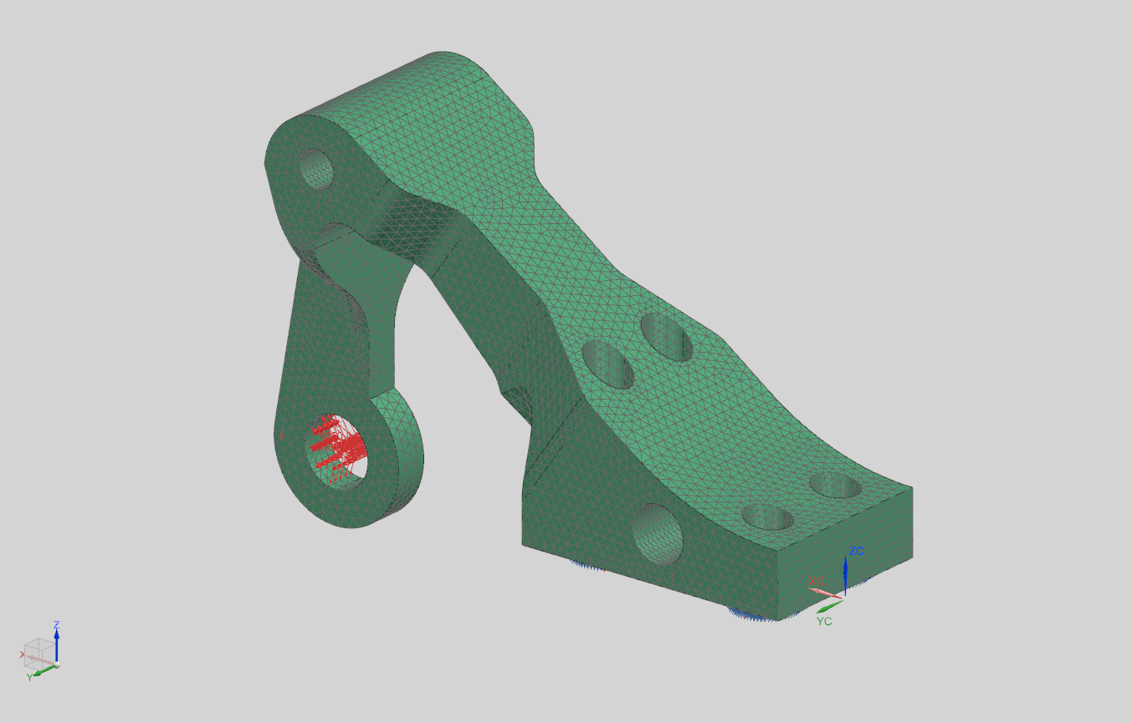

Base Case Finite Element Model

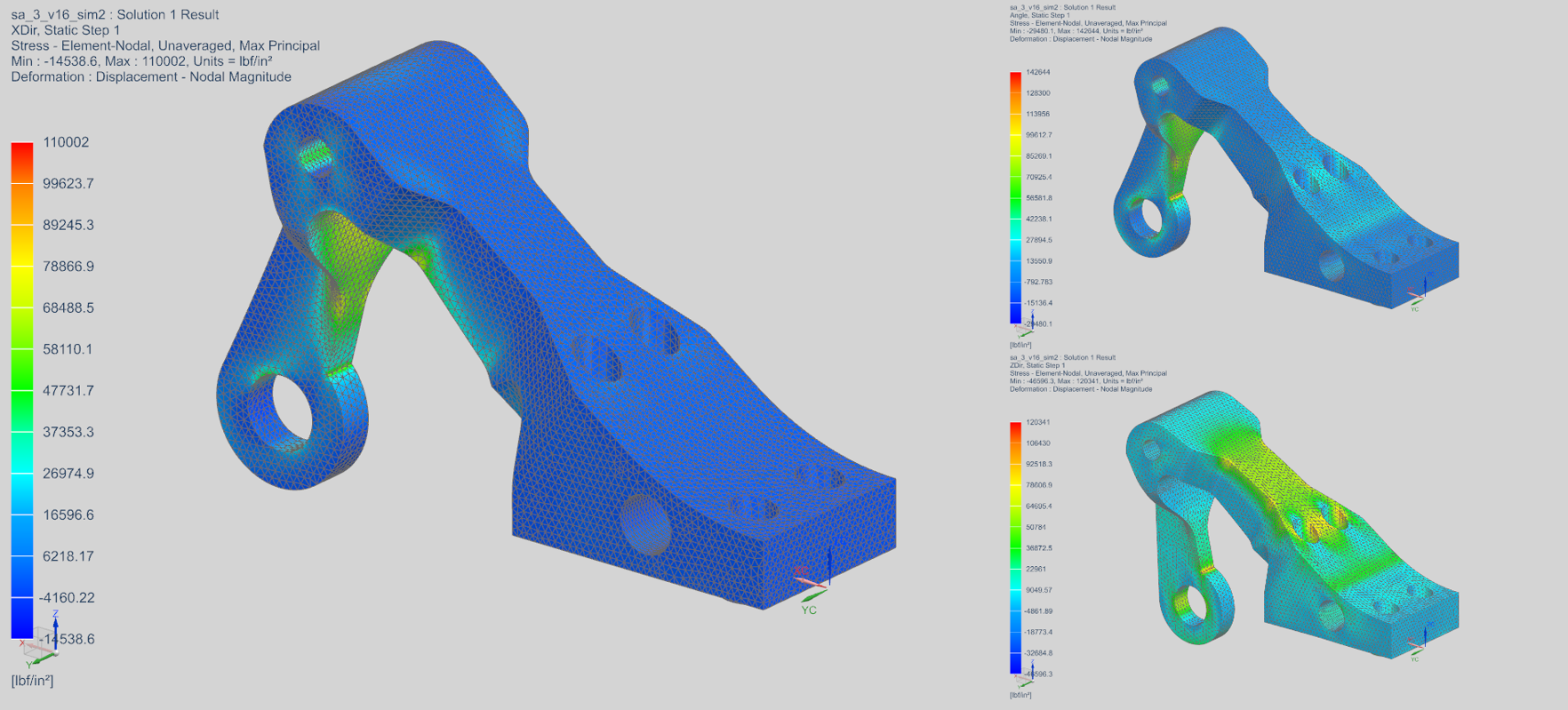

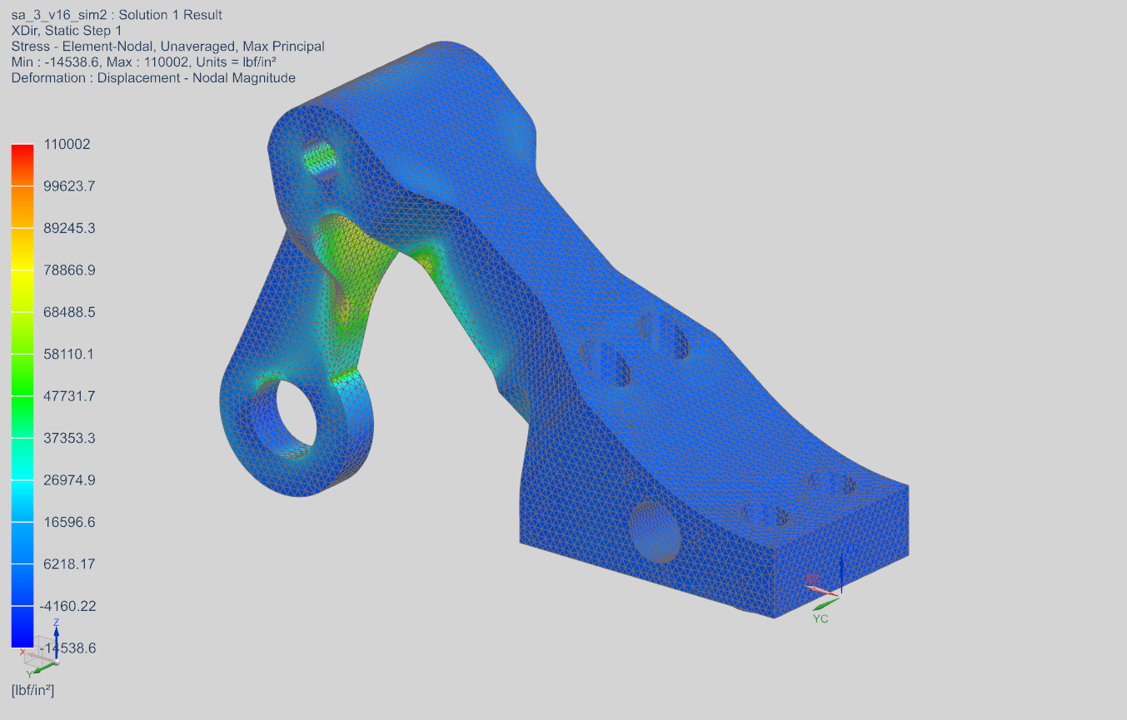

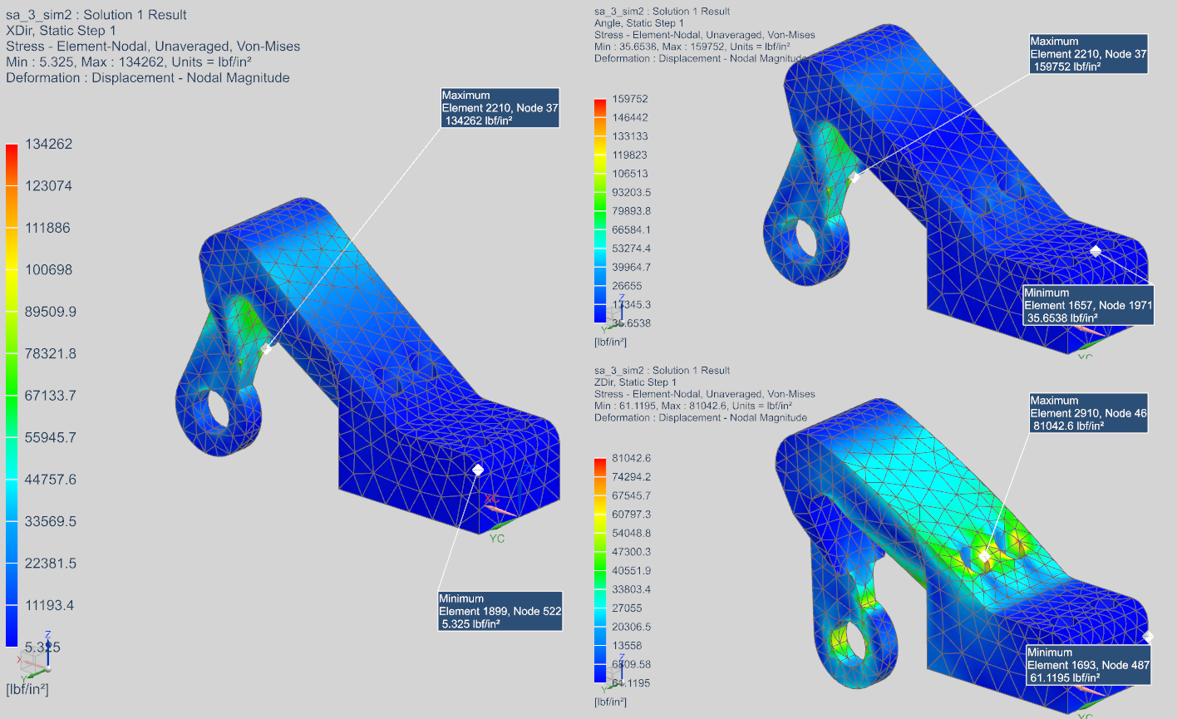

Base Case Finite Element Analysis (Linear Statics)

Design Strategy & Improvements

- Low stress region material removal prioritized to reduce material waste

- Base of hook

- Sides of arm

- High stress region material addition to reinforce weak points

- Wider blends on back face of arm/hook

- Results

- 138% strength-to-weight improvement

- SW = 1126.24

- Validated with <5% convergence study

Optimized Finite Element Model

Optimized Finite Element Analysis (Linear Statics)