Lab’s Goal

Investigate mechano-transduction of the inner ear — how the inner ear selects and amplifies external stimuli. The lab focuses on mechanical interaction between inner ear sensory cells and their surrounding structures.*

My Role

Develop hardware and experiment code for efficient and repeatable dry and wet calibration of artificial membranes by optical coherence tomography (OCT) microscope velocity measurement, acoustic stimulus, and pressure measurement.

Project Outline

Calibration of membranes as pressure transducers requires two components – production of membranes and calibration of a compliance curve for pressure transduction.

- Production – developed by curing UV optical adhesive over laser cut disc with hole in a water bath to generate a thin nanometer scale membrane.

- Calibration – clamping hardware required for use with OCT microscope and acoustic stimuli chamber for applying known pressure to membranes.

- MATLAB algorithm developed using in-house library for OCT control to automate the calibration process.

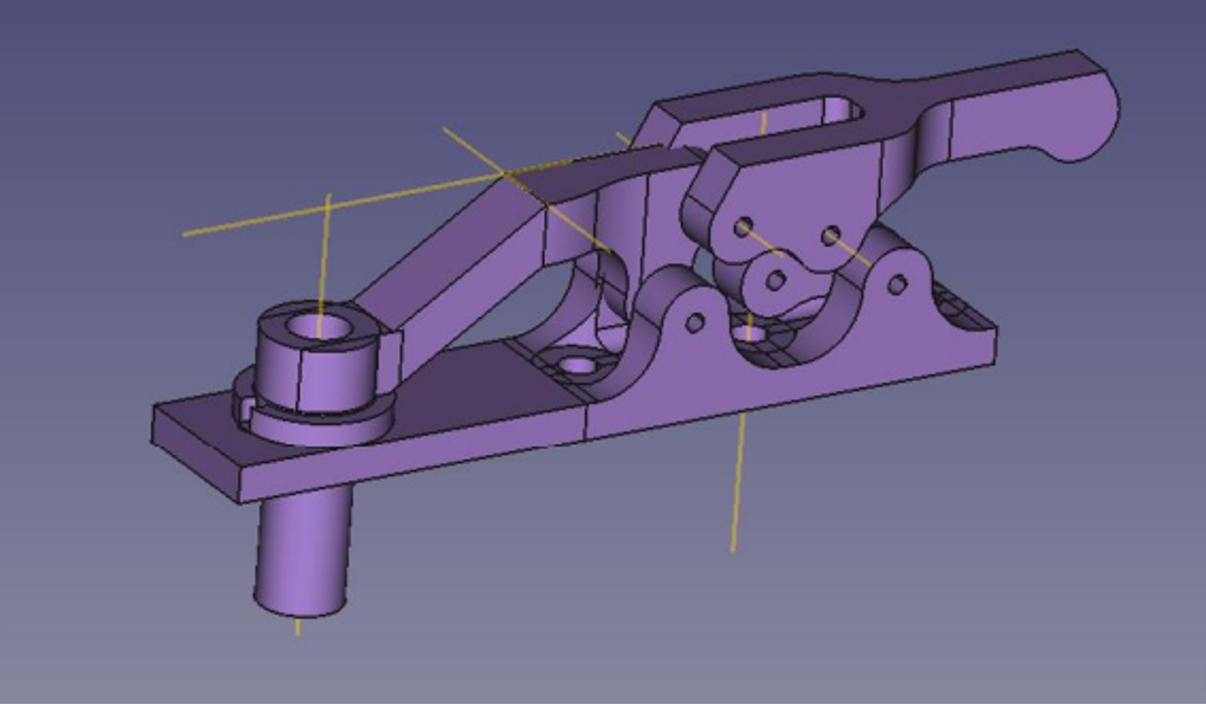

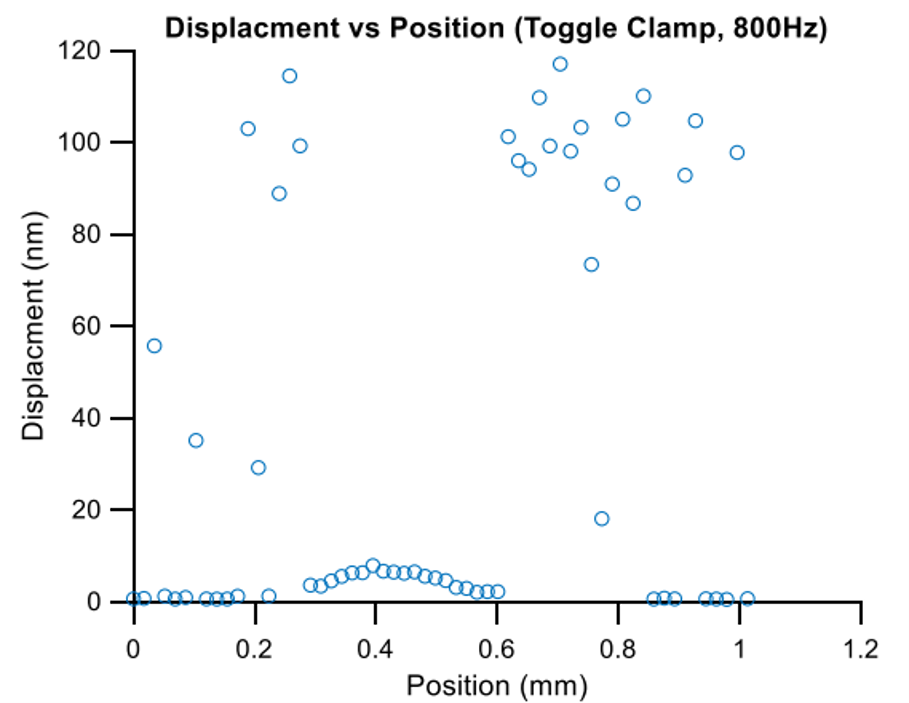

Initial Approach – Toggle Clamp

- Toggle clamp designed for easy and fast placement and calibration of membranes.

- Lateral range of recorded membrane displacements less than known membrane diameter (0.5mm) – suggests insufficient boundary conditions of clamp mechanism. Membrane displacements observed in Figure 1.

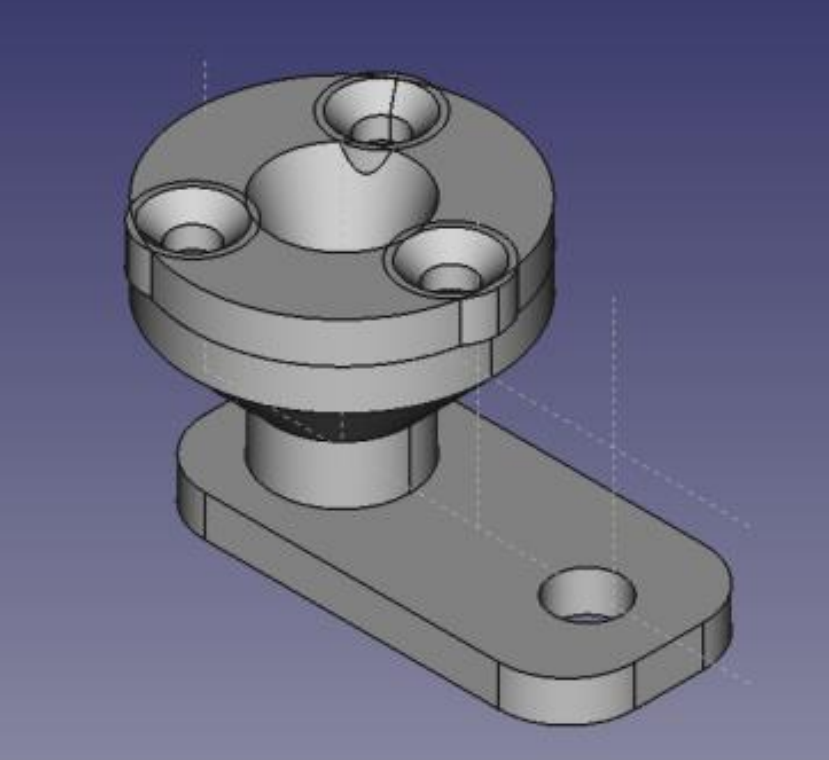

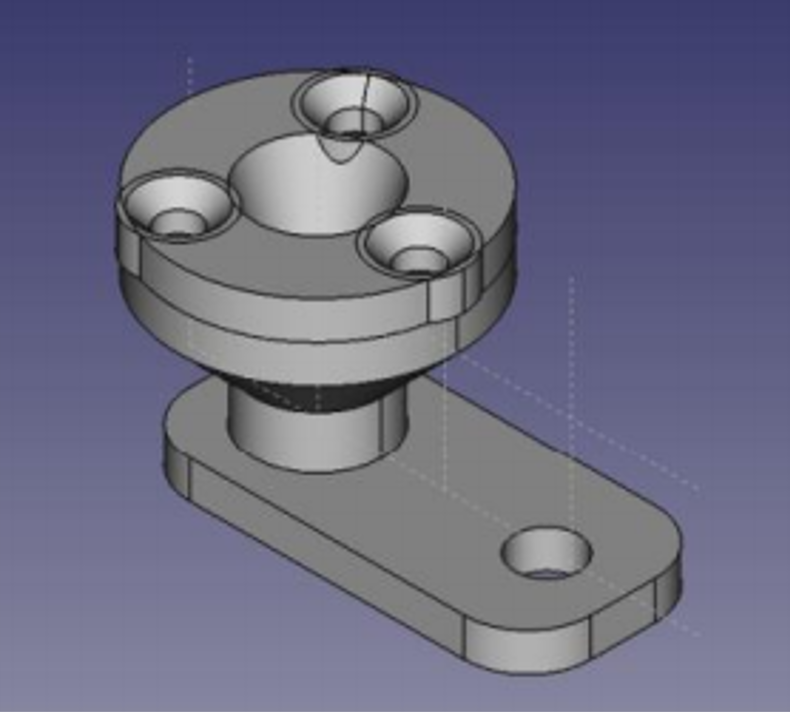

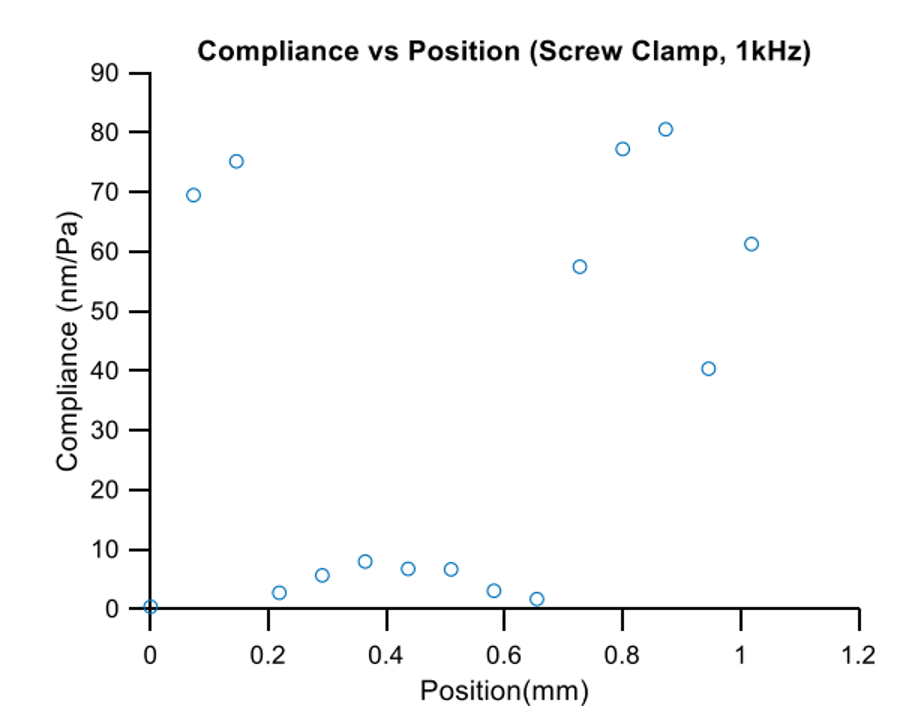

Final Approach – Screw Clamp

- Slower calibration of membrane due to three screws instead of simple toggle lever – compromise for improved boundary conditions.

- Lateral range is 0.5mm (Figure 2), much more reliable hardware.

- Clamp attaches to microscope via screw on base, and microphone for acoustic stimuli raised through hole underneath central membrane hole.

- Non-linear elastomer used under clamping mechanism for reliable seal of membrane under applied pressure.

- FDM 3D printed model designed in FreeCAD. SLA printing used in lab for printing corresponding microfluidic test chambers.

Storage & Indexing

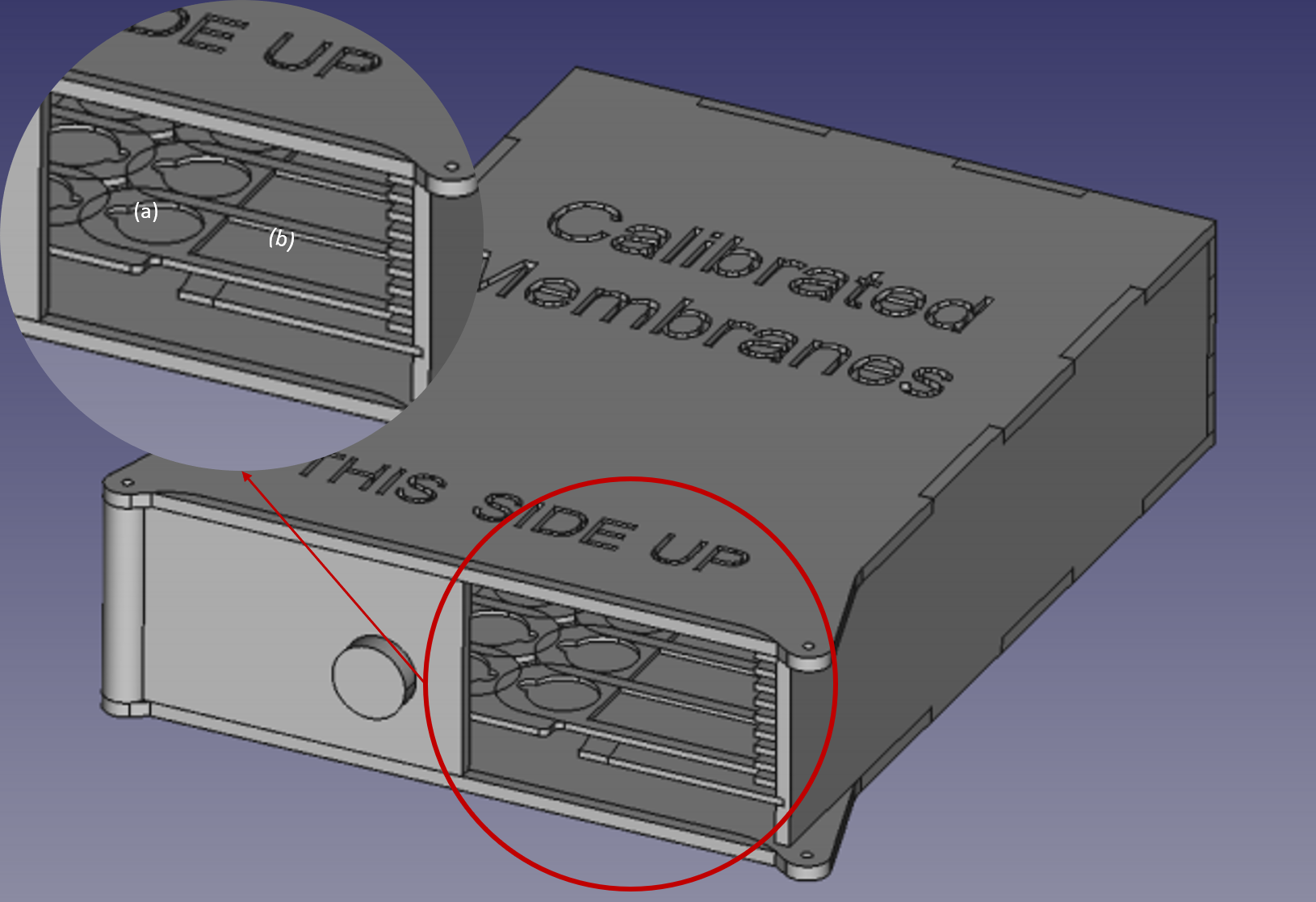

Key Problem

- Lab requires storage and cataloguing of calibrated membranes.

Solution Benefits

- 3D printed system allows easy in-house expansion of storage space.

- Slots for membranes (a) beside slots for membrane index number (b).

- Index number lookup function in spreadsheet on central lab server for reliable use of calibration metrics, including calibration date to account for degradation over time.